A compression tester will give you an idea of whether you cylinder is maintaining the necessary pressure or compression in order to operate properly. If you compression reading are below the Audi specifications then you will need to further troubleshoot using a leak down tester to discover if it is one of the following that is your issue.

The problems you can discover through a leak down test are the following:

- Bad head gasket

- Leaking exhaust valve

- Leaking intake valve

- Bad compression/ oil rings

It is good to check first if the coolant in the radiator has oil droplets inside, and if the oil (most of the times using the dipstick) has water inside.

Then with a compression test you will be able to tell if the piston rings are still ok, if the valves are sealing the chamber properly. However in order to understand how good or bad the engine is, you will need to have the Donkervoort/ Audi compression specs as mentioned below.

Since you removed the spark plugs to do the test, you can check them too, along with their leads. From the spark plugs you can tell how rich or lean the mixture is, or if the motor burns oil. Also inspect the leads for damage, especially on their ends that they meet the spark plugs and on the other end that they meet the coil pack.

Special tools and workshop equipment required

- Spark plug socket and extension -3122 B-

- Compression tester -V.A.G 1763-

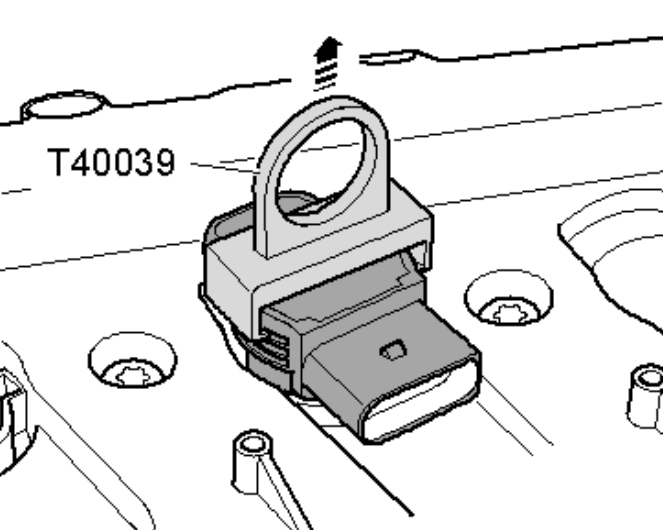

- Puller -T40039- for vehicles with push-fitted ignition coils

Procedure

Engine oil temperature at least 30 °C. Battery voltage at least 12.5 V. Click images to enlarge

- Remove carbon engine cover

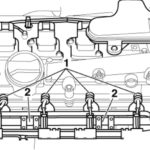

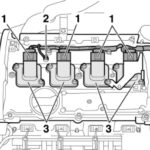

- Unplug electrical connectors -1- on injectors

- Disconnect earth cable -2-

- Pull ignition coils out with puller -T40039-

- Remove spark plugs with spark plug socket -3122 B-.

- Test the compression pressure with the compression tester -V.A.G 1763- or an equivalent aftermarket tool

- Have your friend/mother in law/girlfriend/ wife/ sun /daughter press down the accelerator pedal completely and simultaneously operate the starter until the pressure no longer increases on the tester display.

| Compression pressure | Bar | ||

| When new | 10.0 … 13.0 | ||

| Wear limit | 7.0 | ||

| Difference between cylinders | max. 3.0 | ||

Installation is carried out in the reverse order; note the following:

- Install spark plugs and ignition coils

Note

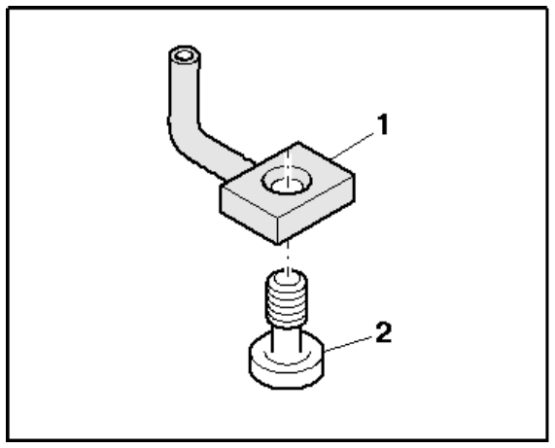

Renew gaskets for bolted on ignition coils if damaged.

- Interrogate and erase the fault memory for engine control unit, as faults are stored when the electrical connectors are unplugged

- Vehicle diagnosis, testing and information system VAS 5051.