Visual inspection of your Donkervoort

It is recommended that after each drive (preferably after washing) you inspect the entire car visually for damage or things that stand out immediately. Take your time. Just take 30 minutes to thoroughly inspect your Donkervoort while enjoying a drink. Develop a hawk eye for details that may not be correct. And compare your car with others. This helps you to get to know your car very well. A lot of misery during long drives can be avoided in advance. Try to address small technical issues as soon as possible. So your car stays reliable and in top condition.

Tip: Use once a telescope mirror (diameter 25-30 mm) with LED for the less accessible areas. On sale at any well-stocked car parts suppliers.

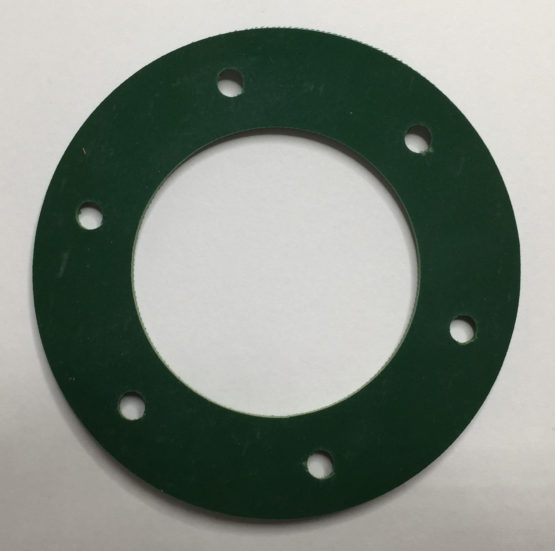

Rubbers

It’s good to inspect or replace all rubber parts every 5-6 years to prevent accidental breakage. All types of rubbers are aging by thermal and chemical attack. Coolant hoses, vacuum hoses, the rubber bushings of the suspension, etc. Do you have an older Donkervoort, then such repairs might be a necessity. Especially when it comes to the reliability of your car. Rubbers are sometimes over 10 years old.

Rubber suspension

Check all components of the suspension regularly visually and “pull” in detached position at the tire / rim to feel if there is free play. Also rotate the wheel in this position to hear if the wheel bearings are in good condition. A key component of the suspension, are the vulcanised bushings.

Suspension bushings, some of the most highly stressed components fitted to your Donkervoort, undergo enormous strain, in the most grueling of conditions with no maintenance or lubrication.

OEM suspension bushings are manufactured from a rubber compound which deteriorates with age. They become softer and more pliable, resisting the forces applied less and less. These tired rubber pieces allow more and more movement of suspension components and offer less and less control over suspension geometry as they age.

Worn parts cause excessive tire wear, braking instability and poor handling. In fact, bushings are the single biggest reason you can instantly tell the difference between an older car and a new one.

These are based on a flex rubber and are applied with the aid of a hydraulic press in the parts of the suspension system. On compression (maximum rotation angle of 20 degrees) to twist these rubbers. Rubbers also have a damping effect, and thereby also provide protection for the copper welding of the chassis. Want a reliable and firm steering car? Have these bushings replaced every 5-6 years at your Donkervoort maintenance point of your choice and align the car again. You notice immediately a huge difference in vehicle handling. A nice winter job.

Steering rack Rubber

The steering rack is mounted to the chassis with two bolds in mounting rubbers.

The foundation for a good steering system and a safe car. Check at least 1 x per year the condition of mounting rubbers, mounting bolts and check that the shims are securely fixed. Also check with the steering rack fully to the left or right rotated that the cycle wings do not touch the vehicle body. If this is the case, it can be easily solved by fitting plastic shims in the steering rack.

Steering bearing Rubber

The steering shaft is -on the steering wheel side – mounted in a self lubricating nylon bearing. This bushing is mounted in a rubber anti-vibration damper.

If there is free- play, it is a significantly less comfortable ride. This bearing is advised to be replaced every five years.

Engine mounting rubbers

The vulcanized two engine mounts and the gearbox rubber tail piece are the only fixation points of the power train. Important for a good and vibration-free operation and proper alignment.

If you have a severe vibration in the drive train, it is important to act quickly, because the engine and drive train are damaged by it. Vibrations are disastrous for these components. Check the engine mounts welded with copper preventive on any breakage or crazing. Replace every 5-6 years, engine strut mounting rubbers and gearbox tail rubber, so that the whole drive train continuous to operate hassle free and reliable. (Photo 3 – Engine Mount Rubber)

Drive shaft covers

The drive shaft protection sleeves are – next to the homo kinetic joints- the most vulnerable part of the drive shafts. It is important that sand and dirt are kept out of the homo kinetic joints. A component to also check regularly and, if necessary, preventive replacement.

Prevention against cracking

Acid free Vaseline can be used to prevent hoses etc. from getting cracked en dried out.