D8 GTO – The differences with the D8

It’s Monday, August 5th, 2013. We have an appointment with Denis Donkervoort himself. It is the start of a new working week, just after the delivery of the first six GTO’s. It has been a very hectic period. Denis makes a relaxed impression. “Do you want a Loosdrechts krentenbolletje with your coffee?” he asks. While enjoying a nice cup of coffee, we try to write down the storyline of the differences between the D8 and D8 GTO. The specifications of both cars are on the table. The first which are so obvious is the difference in torque between the two basic versions. The D8 150 had 210 Nm at 2000 rpm. The D8 GTO Standard with 340 hp has a torque of 450 Nm at the same engine speed. Simply “just” 240 Nm more! Equivalent to a big modern diesel engine! Phenomenal. And the top speed of the GTO is, though obviously less relevant, 25 Km / h higher than the old D8 with 270 hp. Just as we want to go into depth, founder Joop Donkervoort also shows up unexpectedly. He makes a pretty relaxed impression. Perhaps because the last week six cars could be invoiced to the new owners. Such a long period of the development process, which all had to be pre-financed.

Chassis, bodywork and suspension

Joop starts to explain enthusiastically. Almost the entire car is new, compared to the “old” D8. Joop and Denis could not name the exact percentage, when it comes down to how many components are different, but roughly estimated, we arrive at 80-90%. The basis for the GTO was the J-25 chassis. This chassis is a lot longer than the D8. Compared to the D8, the GTO is 330 mm longer, 120 mm wider and 20mm higher.

When we finally took the decision to use the 5 Audi-cylinder engine, we had to make room in the chassis. The new engine periphery is of course a whole lot bigger. The “saw” went into the J-25 chassis, in an ultimate attempt to create the necessary space.

That meant a number of challenges affecting the stiffness of the whole frame and the suspension. “We were really up to the maximum in terms of mechanical grip with the old 270 and D8 GT. A number of customers found the heavily motorized D8 sometimes even scary in some situations and some relationships even wanted to return to the 210 hp version. In developing the chassis of the GTO, we have incorporated that vital feedback, “said Joop.

Dutch support for the suspension development came from Turin. In Turin lives and works the Dutch chassis guru Paul Fickers. Paul now works for the Fiat Group, but in the past was successively working for Ford, Ferrari and Maserati. The well known Revo Knuckle system of Ford, applied to high power front-wheel driven cars, is his invention. “We have a long, solid and high appreciated relationship with Paul. He helped us with the adjustments to the suspension development of the GTO, because he just happened to be working on a similar challenge for Maserati, so that was good timing “says Joop while smiling.

An important difference between the D8 and the GTO, are the number of components which form part of the self-supporting construction. For example, where the hood of the old D8 in that had no function at all, the top engine bay construction is now part of the self-supporting structure. The internal spoiler in the nose cone and the fire wall on the pedal box are now also connected to this engine bay. The new dashboard is integrated both to the chassis as well as the scuttle. Here are some design studies.

Previously, the dashboard was only screwed into the scuttle. “If we had some trouble with annoying rattles, that was also a weak point in the D8. The new scuttle A-style is so strong, it’s like concrete, “claims Joop. The same applies to the rear. “We have a bar attached for added rigidity. Then when we where hit from behind by an Aston Martin GT4 during a race we had only some rubber spots on the back of the GT. A little polish was all. But the front of the Aston, was completely broken, ” explains Denis with a villainous laugh. Sans rancune though! The clever combination of all these measures is to really create a very stiff and rigid car, the traction is really brought to another level.

Doors and RDW (Dutch Authority) demands

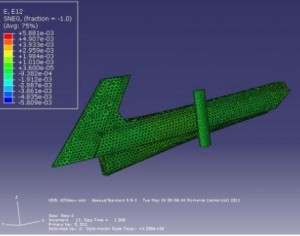

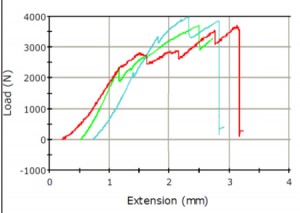

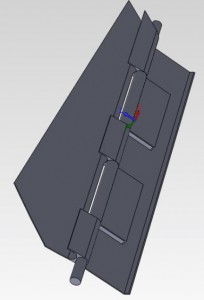

The GTO doors are often referred to as a technological miracle. “Several graduates have joined us engaged in this challenging project. We wanted to open the doors similar to the D8, but an RDW requirement was that you should be able to pull with a force of 1.700 Kg to the doors and that they should be able to cope with a static side impact of 1.500 Kg.

A second important homologation requirement is that the so-called H-point, caused by the A-pillar blind angle must remain limited and that offered little opportunity for a thick A-pillar with hinge, “said Joop. A real challenge. This is also a requirement that applies to any car, small or large, small series or large series homologation, including a car like the GTO. “Initially we looked at standard aluminium machined hinges including the ones from Lotus. But in order to meet the requirements with respect to load-bearing capacity, we had to develop the hinge over the full length of the A-pillar, and in a trapezoidal shape from a single piece of carbon.

The upper doors with a very strong internal side impact structure weigh around 900 grams each. Only the costs to make them are currently exorbitantly high. About 2.800 Euro per door. Those costs must come down. Around these projects we work together with TU-Delft, TU Twente and Ten Cate. You can not develop this know-how autonomously based on this kind of limited production quantities.

The pre-preg techniques we now use are saving us fortunately much valuable production time, “said Joop. The locking system of the doors is an achievement in itself. That is in the case of a collision, the weakest point of the whole structure. The design is made in such a way that if there is an unexpected collision, the door lock themselves are “locking”.

Anti-roll bar

The new anti rol bar construction remains entirely within the car and was also a challenge in itself. “During the GT-4 races we had much corner-exit under steer. There really was the maximum possible achieved by the old anti-roll bar construction. This twisted not only as it should, but also bended as a whole, because he was actually too long and for us as the maximum thickness was achieved (25mm). That was not acceptable. A 270 was, because of that, a bit of a hand full. We wanted to do something about the traction and mechanical grip. So we decided -in collaboration with Paul Fickers – to design a completely different structure for both the front and rear suspension.

A remarkable feature of the front suspension is the in-board stabilizer, operated by levers, the stabilizer gives that much more grip in combination with comfort in a straight line. The GTO has an immense traction and mechanical grip. We have over 130 HP more on board than the 270, but the new chassis is coping with that much more power easily. You do not really notice it in the chassis. Partly due to the INTRAX dampers with ARC “, Joop explains proudly.

Engine

What is striking is that despite the larger 700cc displacement, the engine of the year award winning 2.5-liter is a lot more fuel economical than the proven 1.8 Turbo 20v. It saves an average of 1.0 litres of petrol per 100 kilometres. Partly due to the low weight of the GTO, the CO2 emissions are a pleasant 178 grams per kilometre (D8 = 192 grams). Important in the tax reduction and therefore the actual contribution to the state treasury. And yes, that noise … wow!

Gear box

The GTO is again using the Borg Warner T5 gearbox, but now in a reinforced version. It is a version that is also used in the Ford Mustang. This gearbox can cope with a torque up to 800 Nm. “We thought that it had to be enough. The reason that there is still a relatively old-fashioned gearbox is applied is purely due to the weight and reliability. A PDK is not worthwhile for the Donkervoort. A modern 5- or 6 gear PDK easily weighs more than 80 kg. The weight of the BorgWarner is “only” 32 Kg. Which is currently still the best solution, “explains Joop. The gearbox of the GTO is equipped with synchromesh rings made out of carbon. That ensures very fast syncing and reliable shifting. That this BorgWarner is highly reliable is proved in the gray demo car (#0). This has run over 30,000 kilometres of driving under reasonable journalistic punishment without any kind of problems. “We have such good experiences with this gearbox in terms of reliability, we were even using it during the 24 hours of Dubai,” adds Denis.

Differential

The differential that is still used is still the old reliable design of Ford, which is now being produced already many years by Quaife. For the GTO there are extra reinforcements added in the form of diff brackets. This reaction rods capture the pivotal moment of the higher torque and ensure that the differential does not tear out off the chassis. The final reduction is 3.62: 1 equal to the D8. It is equipped with a 40% Quaife limited slip differential gear (LSD).

Brakes

Joop makes only one joke by saying that the brakes (and therefore the unsprung weight of the car) actually had to be reduced with 100 kilo. “We’re still looking for a bit better, a little lighter and more docile system. In collaboration with TAR-OX we are already a long way, but yeah, you know our search for perfection. “The brakes on the GTO are certainly something else than the D8 and the GT. The discs are 2 mm thinner. This makes them coming earlier on temperature and a little lighter, “adds Denis. What is entirely new; a hand brake system with its own -small and separate- brake blocks.

Rims

“The D8 had rims with an English DNA. Coming from the company Revolution. Originally rims that were used on a Ford Granada. These rims were specially modified for us and made lighter by the center of the hub by machining them. But the centering on the hub was not always precise and accurate because correct casting was quite a sensitive issue. Thereby the risk of some vibration. We have searched for a larger diameter rim with a high degree of perfection. That is not easy because the required rims are not widely used by car manufacturers. Thus also less interesting for the supply industry. It is also important to have continuity in production, since the looks of the rim are also to a large extent determining the design of the GTO. A low weight of the rim is important for a low as possible unsprung weight of the vehicle. We are at a diameter of 17/18 inch because of the strong stabilizing effect. We have chosen for the Japanese manufacturer RAYS to supply the new rims. This ultra-light, forged aluminium wheels are fully adapted to our specifications. And we make it all off with a hub cover of aluminium and wheel aluminium mounting nuts with the Donkervoort logo. It looks gorgeous”, claims Denis.

The hood

The higher top speed of the GTO changes the demands on the hood system. Both in terms of mounting as well as comfort. We have chosen for the insertion of a hard shell on the inside of the roof. And there’s a whole new attachment mechanism designed with a one click mounting system on the backside of the car.

This shows that the GTO looks better, it is much faster to mount than the old tensioning clamp mechanism, and it stays on perfect at high speeds.

If you take all these detail GTO improvements in your mind, nothing else can be the conclusion than that both Joop and Denis had a full head during the last two years. Hats off!

https://www.youtube.com/watch?v=p0cwqhUXJ0k