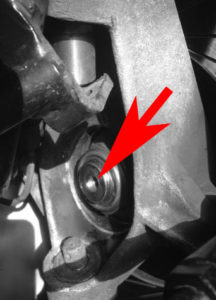

Remove the cycle wing support struts. Prise the aluminium dust cap from the rear of the hub carrier (or upright), and unscrew the hub nut with a suitable high quality socket. Remove the splined washer, and tap the hub carrier from the axle hub. Recover the bearing inner race and rollers from the inner end of the hub carrier (see illustration).

The upright is from a Ford Taunus / Cortina and the inner parts and bearing set is taken from a Ford Sierra.

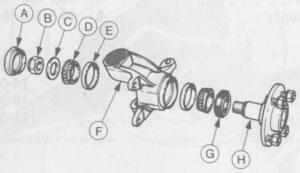

Front hub components – (click to enlarge)

A: Dust cap (aluminium)

B: Hub nut

C: Splined washer

D: Taper roller bearing

E: Bearing outer race

F: Hub carrier

G: Oil seal

H: Axle hub

Prise the oil seal from the outer end of the hub carrier (Special Ford tool 21-051) and remove the remaining bearing inner race and rollers. Using a soft metal drift, drive the bearing outer races from the hub carrier, taking care not to damage the inner surface of the carrier. Clean the hub carrier and axle hub with paraffin, wipe dry and examine for damage and wear. Note that the components are machined to very close tolerances, and the bearings are supplied in matched pairs, therefore scrupulous cleanliness must be observed. Using a metal tube of suitable diameter (or Ford special tool 14-024), drive the new bearing outer races fully into the hub carrier. Ensure that the races are seated correctly.

Pack the inner bearing races and rollers with high-melting-point lithium-based grease (preferably blue TSL grease) , and locate the outer bearing assembly in the hub camber. Fill the cavities between the sealing lips of the oil seal with grease, then drive it fully into the hub carrier using a block of wood or a metal tube of suitable diameter. The oil seal should be renewed regardless of type, and a new seal of the correct type is normally supplied with the new wheel bearings. With the axle hub mounted in a vice, as during dismantling, tap the hub carrier onto the axle hub. Fit the inner bearing assembly, tapping it into place with a metal tube of suitable diameter if necessary, and fit the splined washer.

Pack the inner bearing races and rollers with high-melting-point lithium-based grease (preferably blue TSL grease) , and locate the outer bearing assembly in the hub camber. Fill the cavities between the sealing lips of the oil seal with grease, then drive it fully into the hub carrier using a block of wood or a metal tube of suitable diameter. The oil seal should be renewed regardless of type, and a new seal of the correct type is normally supplied with the new wheel bearings. With the axle hub mounted in a vice, as during dismantling, tap the hub carrier onto the axle hub. Fit the inner bearing assembly, tapping it into place with a metal tube of suitable diameter if necessary, and fit the splined washer.

Note that the bearings are self-setting on assembly, and no subsequent adjustment is required. Refit the hub nut and tighten it to the specified torque (275 – 315 Nm). Tap the dust cap into position in the hub carrier. Remount the cycle wing support struts.